Let's find out when tradition must necessarily give way to innovation.

After being extracted from olives, extra virgin olive oil has an opalescent, cloudy appearance. This is because it contains suspended particles of water and other organic substances—the quantities of which vary depending on the extraction method and the quality of the mill. We're sure you've noticed these residues at least once, clearly visible because they settle over time at the bottom of the storage container or simply at the bottom of your grandmother's or aunt's oil cruet.

This isn't a good sign at all! The coexistence of water, nutrients, and microorganisms can quickly lead to the formation of the sensory defects of sludge and rancidity.

But what exactly happens? Water, dust, soil, proteins, enzymes, and all the suspended matter—composed of olive fragments, pits, leaves, and various impurities—are highly reactive and can trigger degradation processes in the oil.

How can this be fixed? By passing the oil through a porous medium (usually a cardboard filter), foreign bodies and water molecules are retained, effectively eliminating them from the oil. By separating the compounds involved in chemical reactions, the risk of defects occurring is prevented, at least in the short term. Therefore, filtration undoubtedly results in a more stable, clear, and long-lasting product.

This explains why filtering oil extends its life!

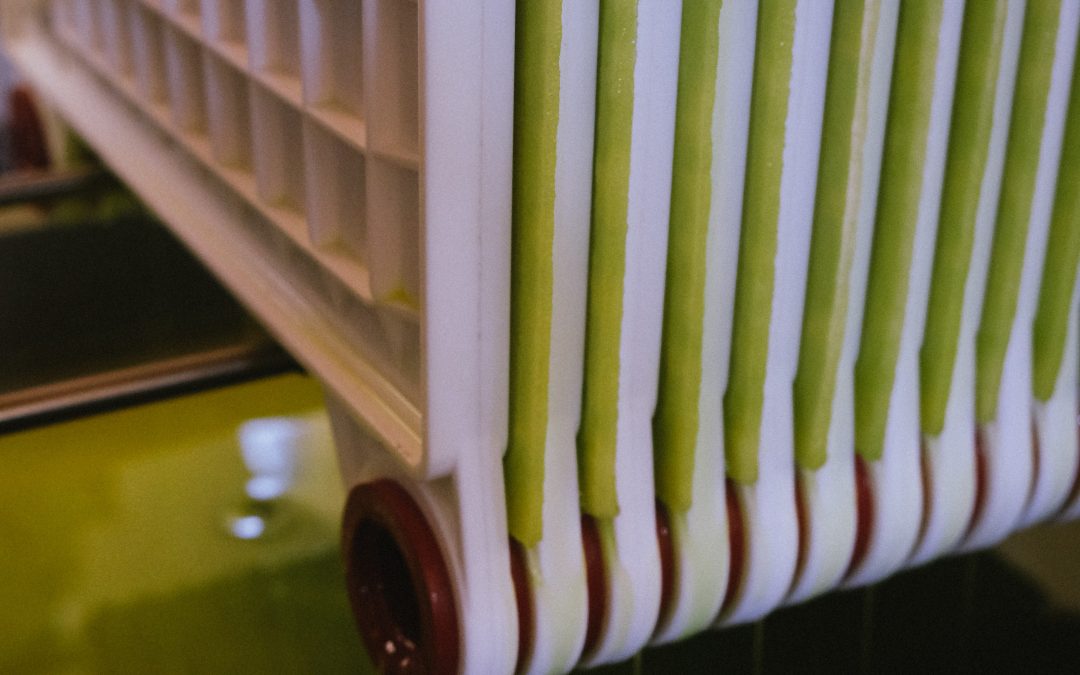

We would like to point out that the filtering process is solely intended to further enhance the quality of the extra virgin olive oil. This additional step in the production process has direct costs in terms of equipment and labor, as well as other costs, such as the inevitable loss of product. Indeed, during each filtering session, a quantity of oil remains trapped in the filters pressed by the machine and is released only at the end of the process (as clearly visible in the video). The oil that falls from the filters collects in the drip tray and is then disposed of.

A quantitative loss entirely justified by a clear improvement in the quality of the product!

So what do we do? We filter!